Does the PCM Control O2 Sensors?

Introduction

The Powertrain Control Module (PCM) plays a crucial role in the operation of a modern vehicle. It is responsible for monitoring and controlling various systems, including the engine, transmission, and emissions. One component that the PCM has direct control over is the oxygen (O2) sensors. These sensors are an essential part of the engine management system, providing valuable data to optimize fuel efficiency and reduce harmful emissions. In this article, we will explore how the PCM interacts with and controls the O2 sensors.

The Role of O2 Sensors

Oxygen sensors, also known as lambda sensors, measure the amount of oxygen in the exhaust gases emitted by the engine. They are located in the exhaust system, typically before and after the catalytic converter. The primary function of O2 sensors is to provide feedback to the PCM regarding the air-fuel mixture’s composition.

By analyzing the oxygen content in the exhaust gases, the PCM can adjust the fuel injection timing and duration to maintain an optimal air-fuel ratio. This ratio is critical for engine performance, fuel economy, and reducing emissions. If the air-fuel mixture is too rich (excess fuel), it can result in poor fuel efficiency and increased pollution. Conversely, if the mixture is too lean (insufficient fuel), it can cause engine misfires and potential damage.

How the PCM Controls O2 Sensors

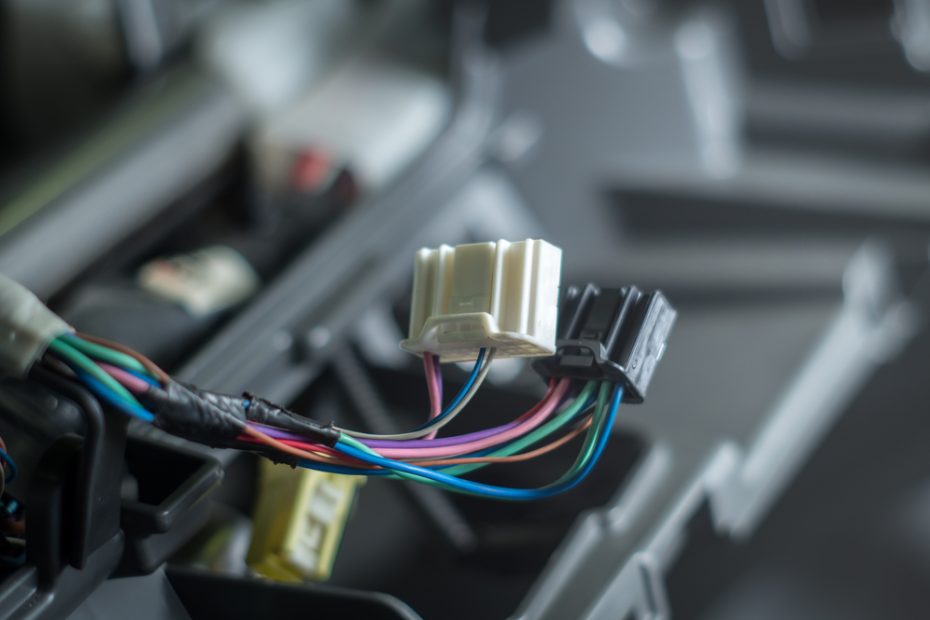

The PCM communicates with the O2 sensors through a series of electrical connections. It supplies them with power and ground connections, and it also receives sensor signals. The sensors generate a voltage signal that varies depending on the oxygen concentration in the exhaust gases. This signal is transmitted to the PCM for analysis and adjustment.

One crucial aspect of the PCM’s control over the O2 sensors is its ability to detect faulty or deteriorating sensors. The PCM constantly monitors the sensor signals and compares them to expected values. If the sensors fail to respond within a predetermined range, the PCM may trigger a diagnostic trouble code (DTC) to indicate a sensor malfunction. This allows technicians to identify and replace the faulty sensor promptly.

Another aspect of O2 sensor control by the PCM is the ability to enter closed-loop operation. During cold start, the engine operates in an open-loop mode, where the PCM uses pre-programmed fuel maps without relying on sensor feedback. As the engine reaches the operating temperature, the PCM transitions to closed-loop operation, where it uses the O2 sensor inputs to fine-tune the air-fuel mixture in real-time. This enables optimal performance and emission control under varying driving conditions.

The Importance of Proper O2 Sensor Function

Proper functioning O2 sensors are vital for maintaining engine performance, fuel efficiency, and emissions compliance. Faulty or deteriorating sensors can lead to various issues, including decreased fuel economy, increased emissions, and drivability problems. Therefore, it is crucial to ensure that the PCM has control over the O2 sensors to detect any malfunctions promptly and make necessary adjustments.

Conclusion

In conclusion, the PCM plays a significant role in controlling the oxygen (O2) sensors in modern vehicles. These sensors provide valuable input to optimize the air-fuel mixture, resulting in improved fuel efficiency and reduced emissions. The PCM communicates with the O2 sensors to monitor their signals, detect sensor malfunctions, and adjust the fuel injection timing and duration accordingly. Proper functioning O2 sensors are essential for maintaining optimal engine performance and meeting emissions regulations. Therefore, it is crucial to ensure that the PCM has full control over these sensors to ensure smooth operation and minimize environmental impact.