How do you diagnose a bad PCM?

Introduction

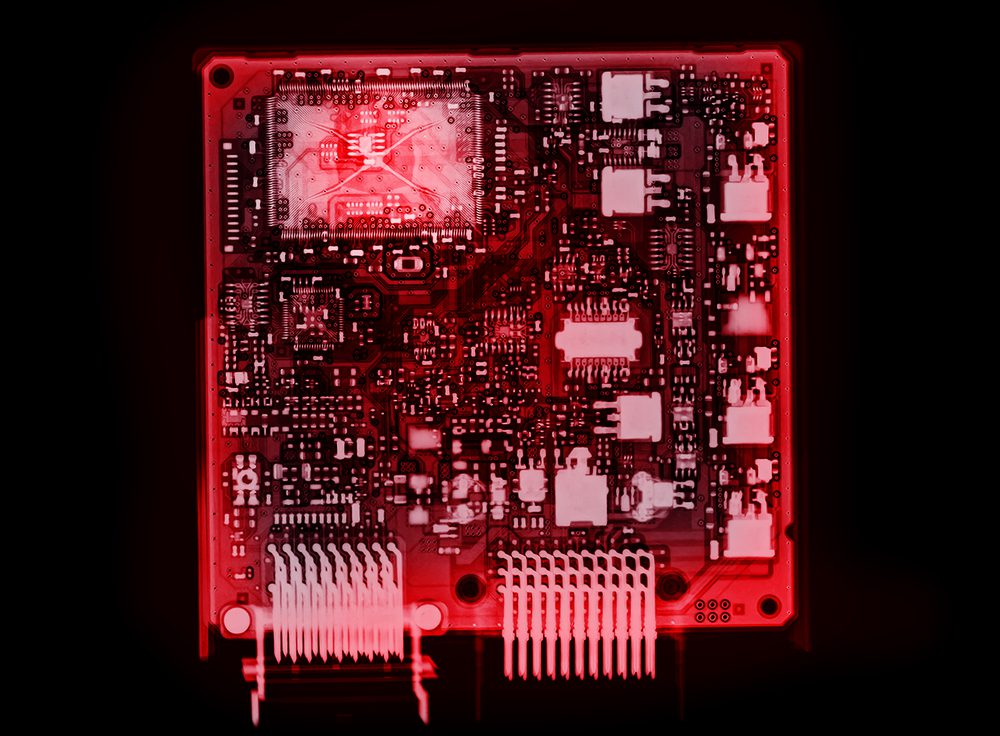

The powertrain control module (PCM) is an essential component of modern vehicles. It acts as the brain of the engine, controlling various functions and ensuring optimal performance. However, like any electronic device, the PCM can sometimes fail or develop faults, leading to issues with the vehicle’s operation. In this article, we will discuss how to diagnose a bad PCM and the steps involved in identifying potential problems.

What is a PCM?

Before diving into the diagnostic process, it is important to understand what a PCM is and its role in a vehicle’s functioning. The PCM, also known as the engine control module (ECM), is responsible for managing and regulating the engine, transmission, and other related systems. It collects data from various sensors and uses it to control fuel injection, ignition timing, emissions, and more.

Common Symptoms of a Bad PCM

A faulty PCM can lead to a range of issues that affect the vehicle’s performance. Some common symptoms of a bad PCM include:

- Engine misfires or hesitation

- Check Engine Light (CEL) illuminated

- Engine stalling or difficulty starting

- Poor fuel efficiency

- Inconsistent or erratic engine behavior

If you experience any of these symptoms, it may indicate a problem with your PCM, although further diagnosis is necessary to confirm the issue.

Diagnostic Steps

When diagnosing a bad PCM, it is crucial to follow a systematic approach to eliminate other possible causes of the symptoms. Here are the steps involved in diagnosing a faulty PCM:

Step 1: Perform a thorough visual inspection

Inspect the PCM for any signs of physical damage, such as burnt components or loose connections. Ensure that all wiring harnesses are securely connected, and there are no obvious issues with the PCM’s external appearance.

Step 2: Retrieve error codes

Using a diagnostic scanner or code reader, retrieve the error codes stored in the PCM. These codes provide valuable information about specific faults or malfunctions in the vehicle’s systems. Pay close attention to any codes related to the PCM itself or its communication with other modules.

Pro Tip: The presence of a PCM-related error code does not always mean the PCM is faulty. It is essential to cross-check the code with other diagnostic tests for a more accurate diagnosis.

Step 3: Test PCM power and ground circuits

Using a multimeter, test the power and ground circuits of the PCM to ensure proper voltage and continuity. A lack of power or ground can cause the PCM to malfunction, so it is crucial to verify these circuits are functioning correctly.

Step 4: Check sensor inputs and outputs

Inspect the various sensors that provide input to the PCM and ensure they are functioning correctly. This includes sensors such as the throttle position sensor, oxygen sensors, and crankshaft position sensor. Additionally, check the outputs from the PCM to actuators like fuel injectors, ignition coils, or transmission solenoids.

Step 5: Perform additional tests

If the previous steps do not lead to a clear diagnosis, further tests may be required. These tests can include checking the PCM’s communication lines with other modules, performing a wiggle test to identify potential wiring or connector issues, or using specialized diagnostic equipment for advanced analysis.

How do I know if my PCM is failing?

The Powertrain Control Module (PCM), also known as the Engine Control Unit (ECU), plays a crucial role in the operation of your vehicle. It controls various aspects of the engine’s performance and monitors the emission system. If your PCM is failing, it can lead to a range of issues that affect the overall functionality of your car. Here are some signs that may indicate a failing PCM:

1. Check Engine Light

One of the most common indications of a failing PCM is the activation of the check engine light on your dashboard. When the PCM detects an issue with the engine or emission system, it will trigger the check engine light to alert you of the problem.

2. Drivability Problems

A failing PCM may cause drivability problems such as rough idling, stalling, poor acceleration, or even difficulty starting the engine. You may experience hesitation or jerking movements while driving, as the PCM may struggle to deliver the correct signals to the engine components.

3. Poor Fuel Efficiency

If you notice a significant drop in fuel efficiency without any apparent reason, it could be due to a failing PCM. The PCM is responsible for optimizing fuel delivery and monitoring combustion efficiency. A malfunctioning PCM may disrupt these processes, resulting in increased fuel consumption.

4. Error Codes

When a PCM encounters a problem, it records error codes, which can be retrieved using an OBD-II scanner. If you find multiple error codes related to the PCM or related systems, it is likely an indication of a failing PCM.

Pro Tip: If you suspect a failing PCM, it is recommended to consult a professional mechanic or auto technician for a thorough diagnosis.

5. Inconsistent Instrument Cluster

A malfunctioning PCM may cause erratic behavior in the instrument cluster, such as incorrect readings on the speedometer, tachometer, or other gauges. If you notice unusual fluctuations or inconsistencies in these readings, it could be a result of a failing PCM.

6. Loss of Communication

In some cases, a failing PCM may lose communication with other onboard modules, resulting in issues with various vehicle systems. You may experience problems with the transmission, ABS, or other electronic components.

7. Electrical Problems

A failing PCM can also cause electrical problems, such as intermittent loss of power to certain circuits or accessories. This can manifest as issues with the lights, radio, power windows, or other electrical components.

8. Engine Misfires

If your engine is misfiring or running unevenly, it could be a symptom of a failing PCM. The PCM regulates the timing and fuel delivery to each cylinder, and any malfunction can disrupt this process, leading to engine misfires.

9. Reduced Performance

A failing PCM can result in an overall reduction in the performance of your vehicle. You may notice reduced power, sluggish acceleration, or a general lack of responsiveness from the engine.

10. Unexpected Shutdowns

In extreme cases, a failing PCM can cause unexpected shutdowns of the engine while driving. This is a serious safety concern and should be addressed immediately.

If you experience any of these signs or suspect a failing PCM, it is crucial to have it diagnosed and repaired promptly to avoid further damage to your vehicle. Consult a qualified mechanic or visit an authorized service center for professional assistance.

What causes PCM failure?

1. Electrical Overload

An electrical overload is a common cause of PCM failure. This occurs when there is excessive voltage or current flowing through the PCM, which can damage its internal components. Factors that can contribute to electrical overload include faulty wiring, short circuits, or power surges.

2. Poor Grounding

Improper grounding is another culprit behind PCM failure. A faulty or inadequate ground connection can cause abnormal voltage levels, leading to damage to the PCM. It is crucial to ensure that all ground connections are secure and free from corrosion or loose connections.

3. Heat and Temperature Extremes

Extreme heat or temperature fluctuations can also contribute to PCM failure. The PCM operates within a specific temperature range, and if exposed to excessive heat or extreme cold, its internal components can become damaged or malfunction. Insufficient cooling or heating systems can exacerbate this issue.

4. Moisture and Corrosion

Moisture and corrosion are common enemies of electronic components, including the PCM. When moisture enters the PCM housing, it can cause corrosion on the circuit board, connectors, or solder joints. Over time, this corrosion can weaken connections and lead to PCM failure.

5. Manufacturing defects

Although rare, manufacturing defects can also be a cause of PCM failure. These defects can include faulty soldering, subpar component quality, or design flaws. If a PCM has a manufacturing defect, it may fail prematurely, even without any external factors contributing to its failure.

6. Age and Wear

PCM failure can also occur simply due to age and wear. Over time, the internal components of the PCM can deteriorate, leading to malfunctions or complete failure. Regular maintenance and inspections can help identify signs of wear and impending failure.

“A well-maintained and properly installed PCM can have a longer lifespan, but it is essential to understand the potential causes of failure.”

Preventing PCM Failure

To prevent PCM failure, it is crucial to take the following steps:

- Ensure proper grounding and electrical connections.

- Protect the PCM from excessive heat and temperature extremes.

- Keep the PCM housing dry and free from moisture.

- Monitor for signs of wear and perform regular maintenance.

- Use high-quality components and avoid faulty installations.

Overall, understanding the potential causes of PCM failure and implementing preventive measures can help prolong the lifespan of your PCM and avoid costly repairs or replacements.